Introduction

Plumbing has come a long way from rigid copper and PVC pipes. Today, flex pipe plumbing has transformed the industry by suggesting elasticity, stability, and ease of erection. Whether you’re a DIY fan or a professional plumbing worker, advancing flex pipe plumbing can assist you sort knowledgeable decisions for your projects.

In this comprehensive deliberation, we’ll discover everything you require to know about flex pipe plumbing—from its types and benefits to assembling techniques, technical specifications, and upkeep tips.

Table of Contents

- What is Flex Pipe Plumbing?

- Types of Flex Pipes and Their Practices

- Technical Specifications of Flex Pipes

- Benefits of Using Flex Pipe Plumbing

- Common Applications of Flex Pipes

- How to Erect Flex Pipes: Step-by-Step Guide

- Tools and Materials Required for Flex Pipe Connection

- Upkeep and Troubleshooting Tips

- Flex Pipe vs. Traditional Plumbing Pipes

- Safety Precautions When Working with Flex Pipes

- Cost Analysis: Is Flex Pipe Plumbing Affordable?

- Common Challenges and How to Overcome Them

- Environmental Impact of Flex Pipe Plumbing

- Future Trends in Flex Pipe Technology

- FAQs on Flex Pipe Plumbing

1. What is Flex Pipe Plumbing?

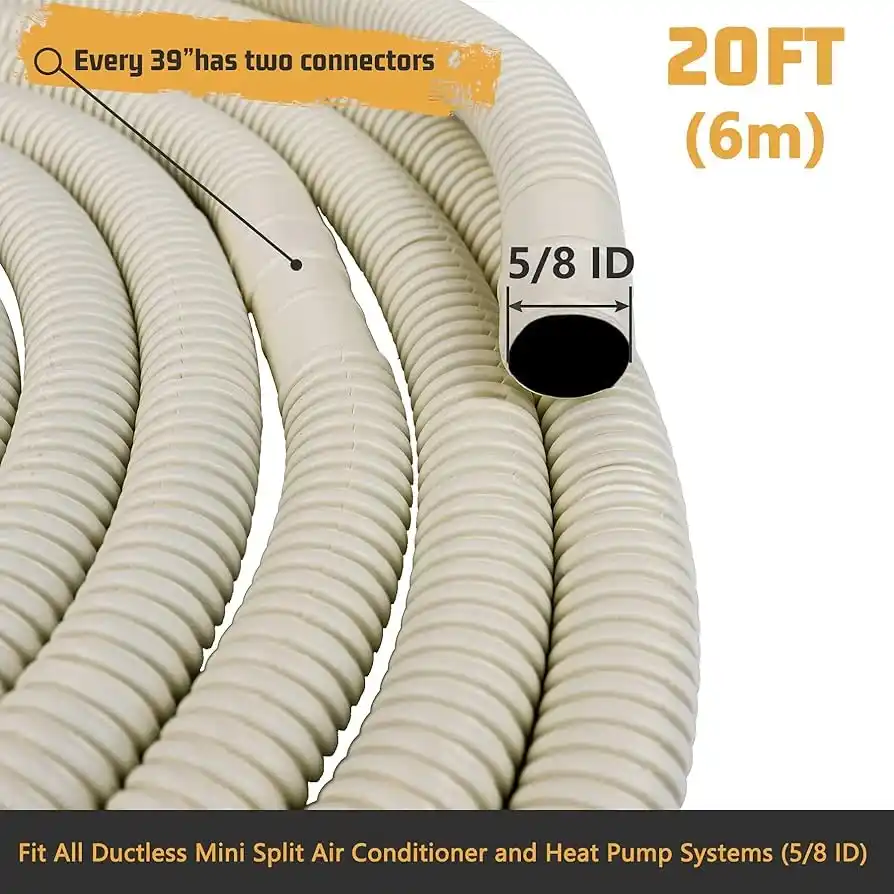

Flex pipe plumbing denotes to the practice of flexible, bendable pipes finished from various materials like PEX (cross-linked polyethylene), stainless steel, and corrugated plastic. Unlike inflexible pipes, flex pipes can turn and coil, making them supreme for spaces with tight corners or complex layouts.

2. Types of Flex Pipes and Their Practices

PEX Pipes

- Usual in residential and commercial plumbing

- Practiced for hot and cold water supply lines

- Sturdy to freezing and bursting

Corrugated Stainless Steel Tubing (CSST)

- Practiced in gas supply lines

- Frothy and corrosion-resistant

- Reduces the risk of leaks compared to traditional metal pipes

Flexible PVC Pipes

- Perfect for irrigation, pools, and spas

- Resistant to UV rays and chemicals

Rubber Flex Pipes

- Normally practiced in industrial applications

- Can endure extreme temperatures and pressures

3. Technical Specifications of Flex Pipes

Understanding the technical aspects of flex pipe plumbing ensures proper selection for different applications.

| Flex Pipe Type | Max Pressure (PSI) | Max Temperature (°F) | Common Diameter (inches) | Typical Lifespan |

| PEX Pipe | 160 PSI at 73°F, 100 PSI at 180°F | 200°F | 3/8” – 1” | 25-50 years |

| CSST (Stainless Steel) | Varies, typically 125-150 PSI | 400°F | 3/8” – 1” | 20-30 years |

| Flexible PVC | 60-80 PSI | 140°F | 1/2” – 2” | 10-25 years |

| Rubber Flex Pipe | 200-300 PSI | 180°F | 1/4” – 2” | 15-30 years |

These values vary depending on the manufacturer and specific pipe grade. Always check product specifications before connection.

4. Benefits of Using Flex Pipe Plumbing

✔ Easier Connection: No require for extensive welding or soldering

✔ Highly Flexible: Can be curved and manipulated into tight spaces

✔ Durable and Long-Lasting: Resistant to corrosion and wear

✔ Leak-Resistant: Less connection points mean fewer potential leaks

✔ Cost-Effective: Demands less fittings and minor labor

5. Common Applications of Flex Pipes

- Home plumbing systems (bathrooms, kitchens, laundry rooms)

- Subversive water supply lines

- Gas pipelines

- HVAC systems

- Irrigation systems

6. How to Erect Flex Pipes: Step-by-Step Guide

- Close the water supply to avoid leaks.

- Record and cut the flex pipe to the desired length.

- Attribute the fittings using clamps or compression rings.

- Safe the pipe using brackets or hangers.

- Shot the water supply back on and check for leaks.

7. Tools and Materials Required for Flex Pipe Connection

- Pipe cutter

- Compression fittings

- Wrench

- Pipe hangers

- Teflon tape

8. Upkeep and Troubleshooting Tips

🔹 frequently examine for leakages around fixtures.

🔹 Clean flex pipes with non-acidic cleaners.

🔹 Check for twists or bends that may disturb flow.

9. Flex Pipe vs. Traditional Plumbing Pipes

| Feature | Flex Pipe | Traditional Pipes |

| Connection | Fast and stress-free | Labor-intensive |

| Flexibility | High | Rigid |

| Cost | Affordable | More expensive |

| Durability | Resistant to corrosion | Can rust or crack |

10. Safety Measurements When Working with Flex Pipes

⚠ always close the water or gas source before connection.

⚠ Practice shielding equipment like gloves and safety goggles.

⚠ Make sure proper provision and securing of pipes to stop wilting.

11. Cost Study: Is Flex Pipe Plumbing Affordable?

✔ PEX piping charges around $0.50 – $2.00 per foot, while copper pipes can price up to $10 per foot.

✔ Labor working rates are lesser since flex pipes demand fewer fittings.

✔ Long-term investment due to condensed upkeep and overhaul requires.

12. Common Challenges and How to Overcome Them

🔸 Kinking – Avoid sharp bends to prevent restricted water flow.

🔸 Fixtures leaks – Practice high-quality compression fittings.

🔸 Compatibility issues – Ensure you choose the right type of flex pipe for your project.

13. Environmental Impact of Flex Pipe Plumbing

🌱 PEX pipes demand less energy to manufacture than copper pipes.

🌱 Reduced waste since flex pipes are highly durable and long-lasting.

🌱 fewer leakages mean less water waste, endorsing sustainability.

14. Future Trends in Flex Pipe Technology

Smart vigilance systems to discover seepages in real-time.

Eco-friendly supplies dropping carbon outline.

Advanced manufacturing techniques improving pipe durability.

15. FAQs on Flex Pipe Plumbing

Q1: What is comparison between flex pipe plumbing and copper?

True, flex pipe plumbing is quite flexible, cost-operative, and easier to erect than copper pipes. Contrarily, copper is sometimes preferred for high-pressure applications.

Q2: Can flex pipes be practiced for hot water?

Sure, PEX flex pipes are intended to handle both hot and cold water proficiently.

Q3: How long do flex pipes work?

Most flex pipes works between 25-50 years, depending on material and upkeep.

Q4: Are flex pipes harmless for drinking water?

Yes, PEX and stainless steel flex pipes are certified for potable water practice.

Q5: Can I erect flex pipes myself?

Absolutely! DIY-friendly flex pipes demand basic tools and minimal plumbing knowledge.

Conclusion

Flex pipe plumbing is transforming the plumbing industry with its broad usability, stability, and cost-efficiency. Either you’re advancing your home’s features or working on a mega-project, flexible pipes suggests a reliable solution for modern plumbing requires.

By understanding the different types, benefits, and fixing methods, you can confidently introduce flex pipe plumbing into your next enterprise.

Would you envision swapping to flex pipe plumbing for your home or business? Let us know your thoughts in the comments.